- Monitoring ammonia leakage in refrigerating plants

- Applicable for a medium temperature of at least -8 ┬░C

- Special PTFE membrane

- Easy replacement of membrane

Liquid Analysis

Liquid Analysis

Comprehensive product range for all analytical parameters Sensors, analyzers and transmitters for on-line measurements of pH, ORP, ion selective electrode activity, conductivity, resistivity and dissolved oxygen.

Ammonia Sensor Exporter

This probe is used to measure ammonia (NH3) in aqueous solutions. In an aqueous solution, ammonia is in a pH dependent balance with ammonia ions (NH4+-Ionen). If the NH4+ ions are transformed into ammonia by the addition of a caustic solution, the probe will record the resulting ammonia. NH4+ ions as such will not be recorded. The ammonia sensor comprises a pH glass electrode and a reference electrode. Both electrodes are immersed in an electrolyte. The electrolyte is separated from the medium to be measured by a hydrophobic gas permeable membrane. The pH value of the electrolyte changes by NH3 gas permeating the hydrophobic membrane. This local change of the pH value is measured by the integrated pH electronic at a resistance. The advantage of the JUMO ammonia probe is the availability of pre-fabricated membrane caps. Manual attachment of the sensitive membrane is not required. The membrane cap of the JUMO probe is easily and quickly replaced as a compelete unit.

Bromin Sensor Exporter

The disinfectant bromine offers a greater disinfectant effect at higher pH values compared to chlorine compounds while at the same time having a lower corrosive effect.Abreacted bromine solutions irritate the mucous membranes to a lesser extent and have a neutral odor.

The membrane-covered, amperometric sensor works on the three-electrode principle. The device is used for the online measurement of hypobromous acid (HOBr). Suitable bromination methods include free bromine (HOBr) as well as 1-bromine-3-chlorine-5.5-dimethyl-hydantoin (BCDMH).

Bromin Sensor Exporter

- Three-electrode principle

- Easy calibration

- Integrated temperature compensation

- Proven measuring system

- Analog and digital version

Drinking water disinfection, Swimming pool disinfection, Service water disinfection, Cooling water

Chlorine Dioxide and Ozone

These membrane-covered amperometric sensors are used to measure the concentration of chlorine dioxide or ozone in aqueous solutions (e.g. drinking water, swimming pool water, industrial water, process water, and cooling water). The sensor for chlorine dioxide can be used to measure chlorine dioxide from chlorite/chlorine and chlorite/hydrochloric acid plants. The sensor for ozone can be used to measure electrolytically generated ozone among other things. The sensors are not suitable for detecting the absence of chlorine dioxide or ozone. The integrated electronics of the sensors provide a temperature-compensated current signal of 4 to 20 mA. A downstream device (indicator, controller, recorder, PLC, etc.) is used for calibration. The sensors can be connected directly to a suitable display and control device

Total Chlorine

Total chlorine is the sum of combined and free chlorine. In all instances, the level of total chlorine will always be above or equal to free chlorine levels. The most common levels of free chlorine present in drinking water are 0.2 to 2.0 mg/L, but can be up to 5.0 mg/L. Total chlorine is usually measured in wastewater that has undergone treatment.

This membrane-covered amperometric sensor is used to measure the total chlorine concentration in water. The sensor also measures "free chlorine" from anorganic chlorine products (chlorine gas, hypochlorite, etc.) and "combined chlorine" (e.g. chloramine). This sensor can only be used in media with drinking or swimming pool water quality. Typical areas of application include swimming pools and monitoring of drinking water.

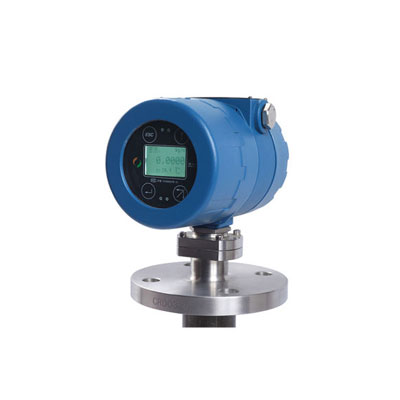

Concentration Transmitter

The device is used for measurement/control of the conductivity/concentration of fluid medium. The application is particularly recommended in media in which severe deposits through contamination, oil, grease, or plaster/calcium precipitations are to be expected. The integrated temperature measurement allows a precise and quick temperature compensation that is particularly important when measuring the conductivity. Additional functions, such as the combined toggling of measuring range and temperature coefficient, allow the optimum use in CIP processes. Two integrated switching outputs can be freely programmed for limit value monitoring of conductivity/concentration and/or temperature. Alarm and control tasks (desalination) can also be assigned.

Concentration Transmitter

- Activation of up to four measuring ranges

- Activation of up to four temperature coefficients

- Concentration measurement

- Fast-response temperature sensor

- Operation via keypad/LCD display or setup program

- Operating language: English, German, French, Dutch, Polish, Russian, Spanish, Swedish

- Setup program for programming/plant documentation

- Learning function for the temperature coefficient

- Individual characteristic for concentration display

- Desalination control

Product separation in the food/beverage industry, Bottle cleaning plants, Concentration measurement, CIP plants, Water and wastewater technology Chemical dispensing

Inductive Conductivity Sensor

conductivity sensors are suitable for the measurement of electrolytic conductivity in aqueous solutions. In contrast to customary two-electrode sensors they offer technical application advantages in the range between medium and high conductance values. Due to the arrangement of the electrodes, these measuring cells can be used for conductance acquisition in water and drinking water treatment, air conditioning technology (cooling circuits), wastewater treatment (water treatment plants), and in ion exchanger plants.

Inductive Conductivity Sensor

- Activation of up to four measuring ranges

- Activation of up to four temperature coefficients

- Concentration measurement

- Fast-response temperature sensor

- Operation via keypad/LCD display or setup program

- Operating language: English, German, French, Dutch, Polish, Russian, Spanish, Swedish

- Setup program for programming/plant documentation

- Learning function for the temperature coefficient

- Individual characteristic for concentration display

- Desalination control

Product separation in the food/beverage industry, Bottle cleaning plants, Concentration measurement, CIP plants, Water and wastewater technology ,Chemical dispensing

Conductivity Sensor

Conductivity sensors are used in conjunction with conductivity transmitters to define the electrolytic conductivity in liquids. The materials in the sensors are physiologically harmless and meet FDA requirements.

Conductivity Sensor

- Fills the gap between conductive and inductive measuring cells

- Very wide measuring range possible

- Hygienic design

- Hygienic process connections

- Adapters enable easy connection to a large variety of processes

- Physiologically safe materials

- Delivery includes quality certificate for cell constant, surface roughness, and FDA approved materials

Rinsing processes in these industries: food technology, beverage technology, pharmaceutical, and biotechnology, Ion exchange plants, Phase separation, Bottle cleaning plants, Process water monitoring

Portable Ph Redox Conductivity

pH value, Redox potential and temperature, or conductive conductivity and temperature respectively in laboratories, industrial plants, in waste water treatment, in fish-keeping or fish-farming, etc. The devices feature a min. and max. value memory and a hold function. To extend the longevity of the battery, the device can be automatically shut down within a time span of 1 minute to 2 hours. Continuous measuring is also possible. The devices are operated using a membrane keypad. The 202710/20 version is a device measuring the pH value, the Redox potenzial as well as the temperature. It is equipped with a manual or automatic temperature compensation for the measured value. The available Pt 100 temperature probe is an optional feature.

Portable Ph Redox Conductivity

- It is used for wide variety of applications such as cheese making, pool maintenance, to grow healthier plants by measuring soil pH, stain removal etc.

- The meters provide numerical value of the pH directly.

- pH meters are very accurate and provide exact pH value with the help of pH sensors.

- It helps in determining how much acidic or basic any substance is.

Chemical industry:Process water, high process pressures up to 13 bar, broad temperature range up to 135 ┬░C, and wide pH range from pH 0 to pH 14 Industrial wastewater engineering: Process wastewater, wastewater with highly contaminated media (oily contents, electrode poisons)

Galvanic: Process water, media with electrode poisons (metal ions, complexing agents) Power plants and waste incineration plants (flue gas scrubbing): Wide pH range of pH 0 to pH 14, presence of fine ash particles Sugar industry: Consistent high temperature, presence of electrode poisons (e.g. sulfides)

ph Sensor Combination Electrodes

A pH measurement loop is made up of three components, the pH sensor, which includes a measuring electrode, a reference electrode, and a temperature sensor; a preamplifier; and an analyser or transmitter. A pH measurement loop is essentially a battery where the positive terminal is the measuring electrode and the negative terminal is the reference electrode. The measuring electrode, which is sensitive to the hydrogen ion, develops a potential (voltage) directly related to the hydrogen ion concentration of the solution. The reference electrode provides a stable potential against which the measuring electrode can be compared.

ph Sensor Combination Electrodes

- Especially robust industry electrodes for the most demanding applications

- For processes with increased pollutant and toxic loads as well as media containing oil

- For high process pressures up to 13 bar

- Wide temperature operating range up to 135ŌĆē┬░C

- Extensive PTFE ring diaphragm or pinhole diaphragm

- HA glass for use in strongly alkaline media

- With quality certificate

- Temperature probe can be integrated as an addition

- Integrated salt reserve

- Double chamber version with dual diaphragm partitioning

Chemical industry:Process water, high process pressures up to 13 bar, broad temperature range up to 135 ┬░C, and wide pH range from pH 0 to pH 14 Industrial wastewater engineering: Process wastewater, wastewater with highly contaminated media (oily contents, electrode poisons)

Galvanic: Process water, media with electrode poisons (metal ions, complexing agents) Power plants and waste incineration plants (flue gas scrubbing): Wide pH range of pH 0 to pH 14, presence of fine ash particles Sugar industry: Consistent high temperature, presence of electrode poisons (e.g. sulfides)

Redox Sensor

ORP is measured using an electrochemical sensor called an ORP or REDOX sensor. Similar to to pH sensors, the most common type of ORP sensor is a combination sensor with a measuring electrode and a reference electrode. The measuring cell, typically a noble metal like platinum or gold, detects changes in REDOX potential, while the reference provides a stable comparison signal.

Like a pH measurement, an ORP measurement is not a direct indicator of concentration, but rather an indicator of activity. However, in solutions with one active species, like pool water containing chlorine, ORP correlates to concentration.

Redox Sensor

- Especially robust industry electrodes for the most demanding applications

- For processes with increased pollutant and toxic loads as well as media containing oil

- For high process pressures up to 13 bar

- Wide temperature operating range up to 135ŌĆē┬░C

- With platinum or gold tip

- Integrated salt reserve

- Double chamber version with dual diaphragm partitioning

With platinum cone: Chromate reduction, Nitrite oxidation, Swimming pool and drinking water disinfection

With gold cone: Cyanide oxidation, Water disinfection

Dissolved Oxygen Sensor

Optical dissolved oxygen sensors feature replaceable caps containing the sensing element: a special dye that will luminesce (glow red) when exposed to light of a particular wavelength. The dye is covered by an oxygen permeable paint layer, which allows oxygen molecules to interact with the dye, while protecting it from other sample constituents. Oxygen interferes with the dyeŌĆÖs luminescence (intensity and lifetime). The sensor emits light and measures the resultant luminescence with a photodiode. This reading is compared to a reference reading using light of a different wavelength. The measurement and reference values are compared to calculate dissolved oxygen in the sample.

Dissolved Oxygen Sensor

- Measurement of dissolved oxygen (DO) in aqueous solutions

- Safe 1-point calibration

- 2-wire transmitter (for basic and standard version)

- Electrical isolation of measurement signal (DO) and output signal (mA)

- Easy connection to an existing system (e.g PLC)

- Can be used as stand-alone system in maximum version

- Compensation of temperature, atmospheric pressure and salinity

- Further processing of the temperature of the medium is possible (separate Pt 1000 or 2-wire transmitter)

- Setup program for comfortable transmitter configuration / documentation

- Easy, safe service by replacement of modules

- Background lighting (for maximum version)

Communal and industrial waste water treatment plants, Drinking water monitoring, Protection of water bodies, Fish keeping/hatchery plants, Technical processing plants

Turbidity Sensor

Turbidity sensors measure the amount of light that is scattered by the suspended solids in water. As the amount of total suspended solids (TSS) in water increases, the waterŌĆÖs turbidity level (and cloudiness or haziness) increases. Turbidity sensors are used in river and stream gaging, wastewater and effluent measurements, control instrumentation for settling ponds, sediment transport research, and laboratory measurements.

Turbidity Sensor

- Measuring method based on the 90┬░ scattered light procedure according to DIN EN ISO 7027

- Entire measuring range 0 to 4000 NTU

- Four single measuring ranges (adjustable) as well as automatic measuring range detection

- Secure, digital measured value transmission

- High measuring accuracy, even for low turbidity

- Integrated temperature sensor

- Short response time

- Sensor is precalibrated prior to shipment

- Protection type IP68

- Operating temperature from 0 to 50 ┬░C

- Safe use when the corresponding fittings are used

Process monitoring in the treatment of drinking water and wastewater Municipal and industrial sewage treatment plants Monitoring of bodies of water Fish farming companies Galvanic Process plants